PROJECT DESCRIPTION

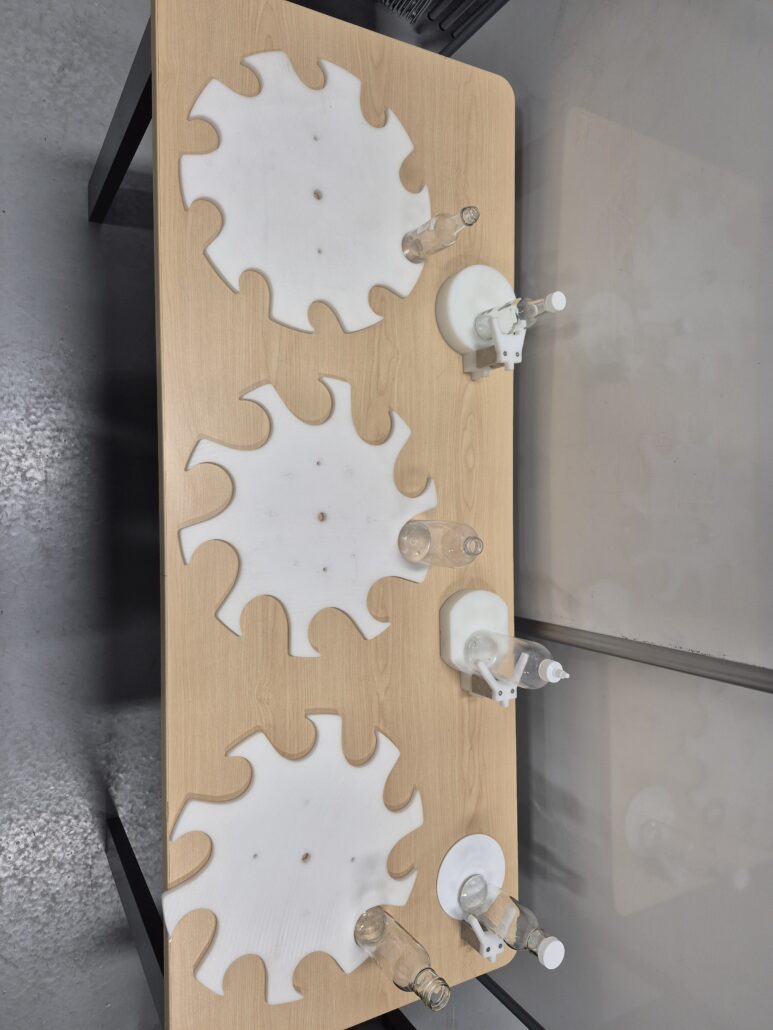

Development of an automated process to fill and cap containers of various sauces and spices, previously performed manually. Existing automated solutions were prohibitively large and expensive given the small size of the company.

Methodology

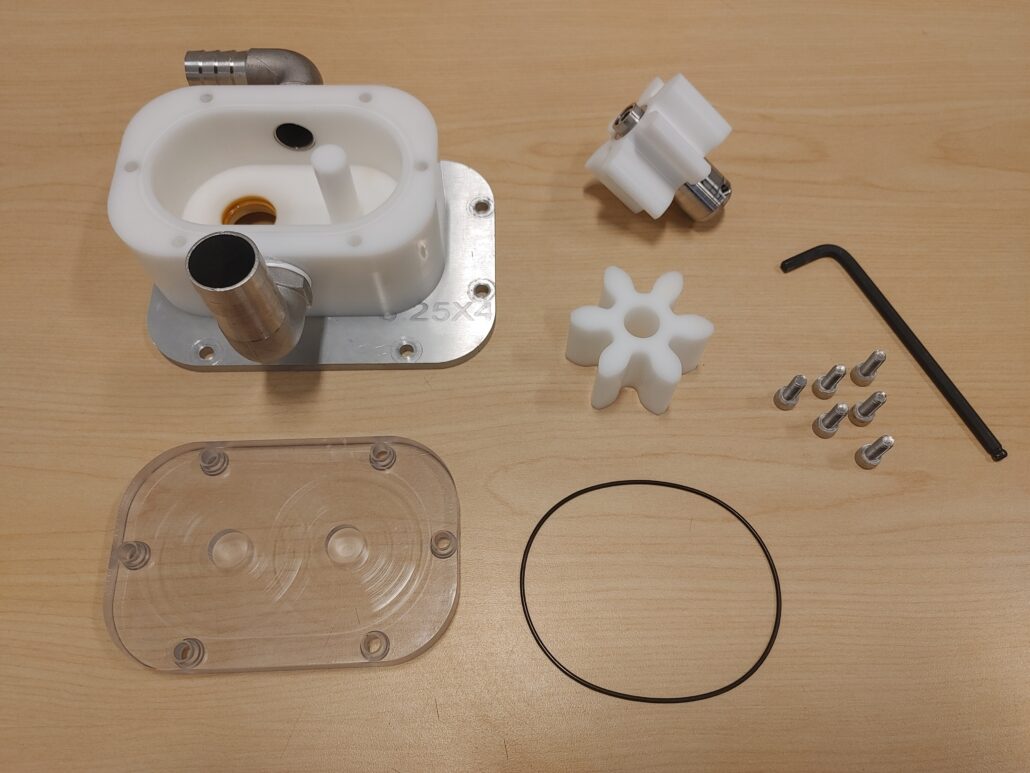

After an exploratory visit to examine the existing site, the project used iterative design and manufacture of a mechanical, electrical, and electro-pneumatic control system, with lab and in situ tests of the equipment carried out to validate the process.

Requirements from the school and teacher

Mechanical engineering knowledge, manufacturing knowledge and CAD design knowledge.

Requirements from the company

Detailed knowledge of bottling process and factory setup. Provision of samples of sauces, containers, cap, employee presence and contribution to testing of the automated bottling process.

Resources

3D printers, CAD, CNC machiens

Results and achievements

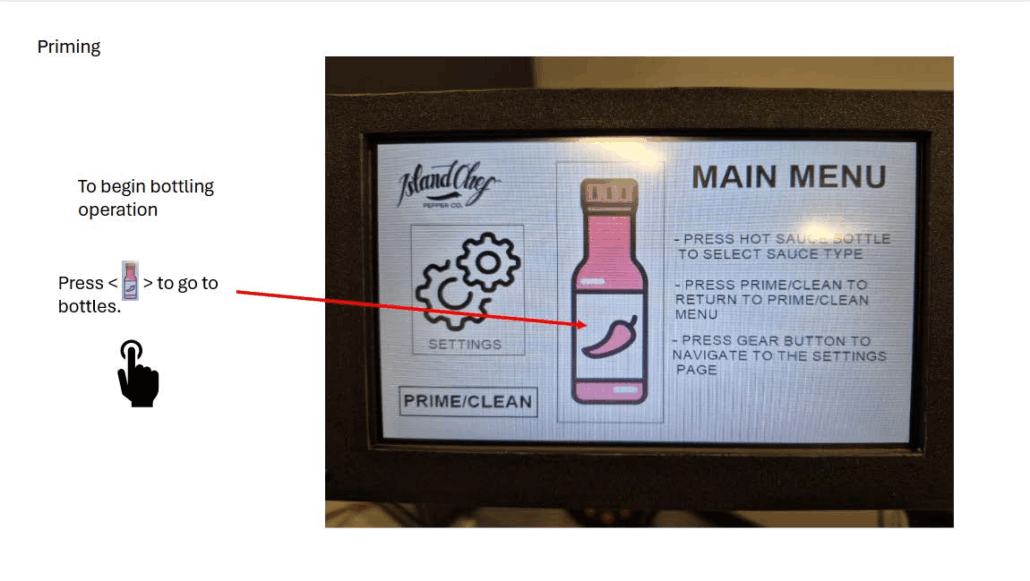

A fully automated bottling line was developed, along with documentation and digital integration.

Significant increase in company’s capacity to bottle and distribute goods.

Company website:

https://www.islandchefpepperco.ca